Featured Resources

Change Orders, Productivity, Overtime—A Primer for the Construction Industry

This planning tool helps you determine the costs associated with unplanned events, circumstances and factors that may impact the outcome, productivity and schedule of construction projects. New for 2024: a chapter exploring the factors that contribute to BIM cost and time overruns.

Mental Health Awareness & Suicide Prevention Video

Our newest safety and health video highlights the success story of an industry veteran, with appearances from MCAA’s president Robert Beck, the UA’s Jen Massey, industry expert Dr. Sally Spencer Thomas, and MCAA member Ricky Reams.

WebLEM is the industry’s most reliable authority for comprehensive labor units for typical project tasks. Quickly search for and retrieve information. WebLEM is reviewed and updated to reflect the latest products and joining methods. You will need your MCAA.org username and password to log in to WebLEM. For WebLEM access questions, please refer to the WebLEM Access FAQs page.

National Service and Maintenance Agreement

The National Service and Maintenance Agreement is an agreement negotiated and administered by the United Association of Journeymen and Apprentices of the Plumbing and Pipefitting Industry (UA) and the Mechanical Service Contractors of America (MSCA) and is a signed contract between the UA and individual mechanical service contracting firms who apply and qualify. The Agreement is a nationally recognized tool that helps contractors provide quality, consistent service to their customers throughout the country and helps reclaim lost market share.

Gary Moore, Executive Vice President and Chief Revenue Officer of Victaulic®, will retire at the end of April after 37 years of distinguished service with the company. Mark Gilbert, currently Vice President and General Manager for Europe, Middle East, and Africa, as well as Vice President in the U.S., will succeed Moore as Executive Vice President of Sales, effective May 1, 2025.

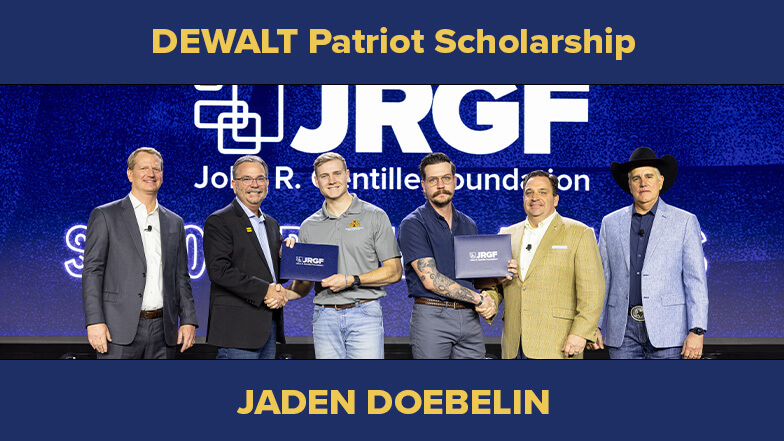

Jaden Doebelin has been serving in the United States Iowa Army National Guard for over five years and is currently a non-commissioned officer, holding the rank of Sergeant. He is studying Construction Engineering and will graduate this May from Iowa State University. He previously interned with MCAA Member, Baker Group, and plans on working full-time at a mechanical contracting company upon graduation.

Don’t miss out on the upcoming PCA Plumbing Service Conference! May 19-21, 2025, in St. Louis, this event is your best opportunity to learn, share, and grow in your understanding of operational plumbing service. With industry leaders, in depth tours, and invaluable networking, this is a conference you don’t want to miss. Sign up now!

The ripple effect of change begins with one small action – and in the mechanical industry, women are making waves. The WiMI Conference offers an unparalleled opportunity to connect with like-minded professionals, gain valuable knowledge, and be inspired by the journeys of those who have dared to lead. Whether you’re new to the industry or a seasoned executive, the WiMI Conference is a platform for you to find your voice and expand your influence within the industry. Join us at the WiMI Conference – empower yourself, connect with others, and leave ready to make your mark on the industry. Register now!

The National Certified Pipe Welding Bureau (NCPWB) has released a new Technical Bulletin explaining the term “backing” that appears in Welding Procedure Specifications (WPSs) or welder qualification records. The bulletin explores what welding backings are, when they must be used and when they are optional.

MCAA’s Virtual Trade Show connects our contractor members with the members of MCAA’s Manufacturer/Supplier Council.

NIBCO INC. unveiled the Rex Martin NIBCO Interactive Museum on November 12, 2024, coinciding with NIBCO’s 120th anniversary. The museum offers a unique and enriching experience from a historical perspective, interactive learning, inspiration, community impact, and career opportunities. Not just a place to learn about the past, it’s a place to get excited about the future of plumbing and the opportunities it holds. NIBCO INC. is a major sponsor of MCAA25.

Jennifer Tartaglia is a Mechanical Engineering major at the University of Maryland, College Park and is anticipated to graduate this spring. She has been an active member of her student chapter for the past two years and currently serves as the UMD Student Chapter President. Last summer, Jennifer interned with MCAA Member, Harris.

Field leaders looking to enhance their leadership skills and industry knowledge will benefit from MCAA’s May Field Leaders Conference, being held Monday, May 12 – Wednesday, May 14 at the Hilton Washington DC National Mall The Wharf. The event is nearing full capacity. Don’t miss this opportunity to register your field leaders today!

Service technicians may work on their own without ready access to assistance. MCAA’s Lone Worker Safety Model Program helps contractors identify risks and hazards and ensure adequate systems are in place to protect those workers. It’s just one of MCAA’s educational resources that are free to MCAA members as a benefit of membership.

MCAA has joined forces with the National Fire Protection Association (NFPA) to offer resources and tools customized and curated to specifically address and mitigate risks related to electrical safety posed to MCAA members, including physical, compliance and financial risks. Crafted by NFPA’s trusted subject matter experts, this content will provide actionable information and strategies to help you and your team keep pace with the ever-changing regulatory environment, identify potential hazards and shortfalls, and markedly improve safety for your employees, customers, and their workplaces and communities.

The Manufacturer/Supplier Training area of MCAA’s website connects our contractor members with training opportunities available from the members of MCAA’s Manufacturer/Supplier Council.

MCAA’s web-based labor estimating manual is an invaluable tool for your business. Free as a benefit of your membership.

WebLEM

Scholarships are just one way the John R. Gentille Foundation is investing in your industry’s future. Have you invested in it?

JRGF

You can make an impact on the future of your industry and your business by contributing to the MCAA Political Action Committee.

MCAA PAC

Looking for an intern? You can head to our improved student chapter website and check out the great resumes there!

MCAAGreatFutures

The year-round involvement of our manufacturer/supplier members is part of what makes MCAA special. Learn more about the Council and the value it brings to MCAA.