Category: Featured Resource

Understanding the implications of the Inflation Reduction Act and its impact on pricing jobs for installing heat pumps or heat pump water heaters can be daunting. However, a new resource from ENERGY STAR aims to simplify this process, specifically tailored for selling and installing Air Source Heat Pumps, Heat Pump Water Heaters, and Electric Panel Upgrades. It’s crucial for both contractors and property owners to grasp these credits, as they can cover up to 30% of project costs.

Two prevalent misconceptions revolve around the effectiveness of heat pumps in colder climates and their serviceability. To address these misgivings and better equip professionals for customer discussions, MSCA contractors and ENERGY STAR have developed a concise reference guide. This resource not only tackles these challenges head-on but also aids in preparing individuals for productive conversations with clients who hold these perceptions.

Two prevalent misconceptions revolve around the effectiveness of heat pumps in colder climates and their serviceability. To address these misgivings and better equip professionals for customer discussions, MSCA contractors and ENERGY STAR have developed a concise reference guide. This resource not only tackles these challenges head-on but also aids in preparing individuals for productive conversations with clients who hold these perceptions.

This full-featured digital version of our Membership Directory & Buyer’s Guide enhances the look and feel of our printed directory with digital-only benefits.

This quick reference tool provides critical information on 61 safety and health topics that are specific to work performed by mechanical fabrication shop workers. The topics include everything from bloodborne pathogens through welding-cutting-heating, and zinc exposures. The manual also includes updated information on how to properly administer CPR.

This quick reference tool provides critical information on 84 safety and health topics that are specific to work performed by mechanical service technicians, including information on the newest and most frequently used refrigerants, substantive changes to NFPA 70E, and new information on how to properly administer CPR.

This quick reference tool provides critical information on everything from aerial lift safety to preventing overexposure to zinc to keep mechanical construction workers safe. It includes new information on administering CPR, beryllium, recent changes to NFPA 70E, and more.

NFPA 70E – 2021 states that each employer shall implement and document an overall electrical safety program that directs activity appropriate to the risk associated with electrical hazards. This model program, which is based largely on information from NFPA 70E – 2021 articles 110 – General Requirements for Electrical Safety-Related Work Practices, 120 – Establishing an Electrically Safe Work Condition, and 130 – Work Involving Electrical Hazards, will help you develop an electrical safety program that is specific to your company’s needs.

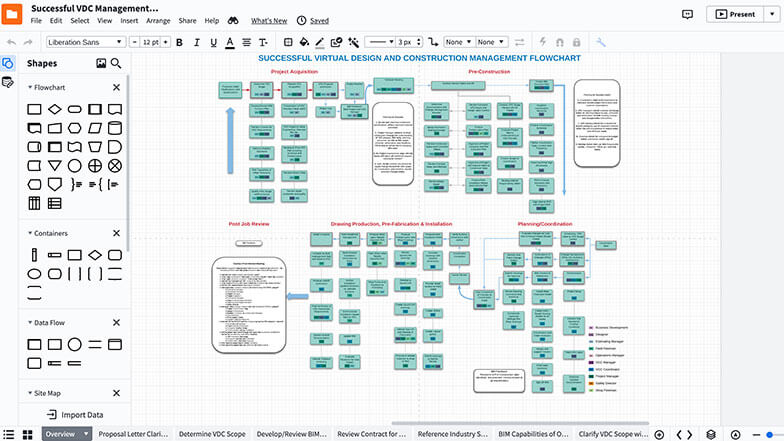

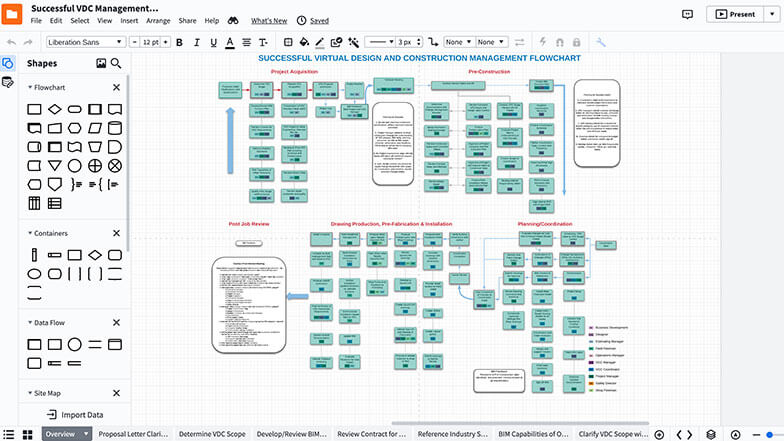

The best way to understand your company’s technology challenges is to understand your processes. This workflow tool helps you understand and document your company’s entire project management flow, including the application of fabrication, BIM and Virtual Design and Construction (VDC) processes. It identifies in detail the potential implementation of VDC throughout each phase of the project lifecycle and details the team members involved and their specific responsibilities for each phase of the construction process. (Note: MCAA members will need to set up a free Lucidchart account and create a copy of the template to customize the flowchart for their company’s processes.)

Quick rescue is paramount to keeping workers safe while they are suspended in fall arrest harnesses after falling from an elevation. Having a safety program and plan in place to address the needs of these workers is critical to minimizing suspension trauma and meeting OSHA requirements. MCAA’s model program and accompanying model plan can be tailored to address various project fall arrest system applications and ensure the safety of your company’s most important asset, its workers.

MCAA has joined forces with the National Electrical Contractors Association (NECA) and the Sheet Metal and Air Conditioning Contractors’ National Association (SMACNA) to create an even more robust guide to equipment recovery costs for mechanical, electrical, line and other construction contractors. The guide offers insights on contractor-owned equipment to ensure industry professionals have the most updated costs to inform internal estimating, project proposals for new and potential customers, and cost accounting efforts.

This planning tool helps you determine the costs associated with unplanned events, circumstances and factors that may impact the outcome, productivity and schedule of construction projects. New for 2024: a chapter exploring the factors that contribute to BIM cost and time overruns. This resource is a must-have for mechanical and other specialty contractors, attorneys in construction practices, and consultants.

The use of BIM and related technologies and processes that leverage data from models is delivering meaningful impact to mechanical and HVAC contractors on a wide variety of measures, including cost and schedule improvements, enhanced productivity, better collaboration between stakeholders and better worker safety. This research report quantifies other benefits to users and the challenges related to leveraging BIM to increase industry understanding of which factors will most effectively drive growth and expand future use.

Sorry, but you do not have permission to view this content.

Improved productivity and quality are among the benefits driving interest in, and use of, prefabrication and modular construction today. This research report quantifies other benefits to users and the challenges related to each to increase industry understanding of which factors will most effectively drive growth and expand future use.

Sorry, but you do not have permission to view this content.

Motion is money and safety in the construction business, which relies on employees’ physical movements to accomplish the job at hand. This video will teach your supervisors to recognize opportunities to minimize movement, leading to safer and more profitable jobs.

Supervisors will learn:

- How unnecessary walking, bending, reaching, climbing, pushing, pulling, lifting, and carrying increase the risk of cumulative trauma injury to the soft tissues

- How unnecessary movement increases the risk of injuries from slipping, tripping, and falling

- How increasing productivity reduces the risk of injury

- The importance of consistent storage and staging of materials, tools, and equipment

- Why pre-planning each task is critical to reducing unnecessary motion

- How to start the process by observing your workers for 30 to 60 minutes

Protect your workers with the safe work practices in this guide. It covers the hazards associated with RF radiation exposure, the health effects posed by these hazards, and how to avoid overexposure. A checklist helps workers assess their work areas for sources of RF radiation. See the related tools for educating your workers.