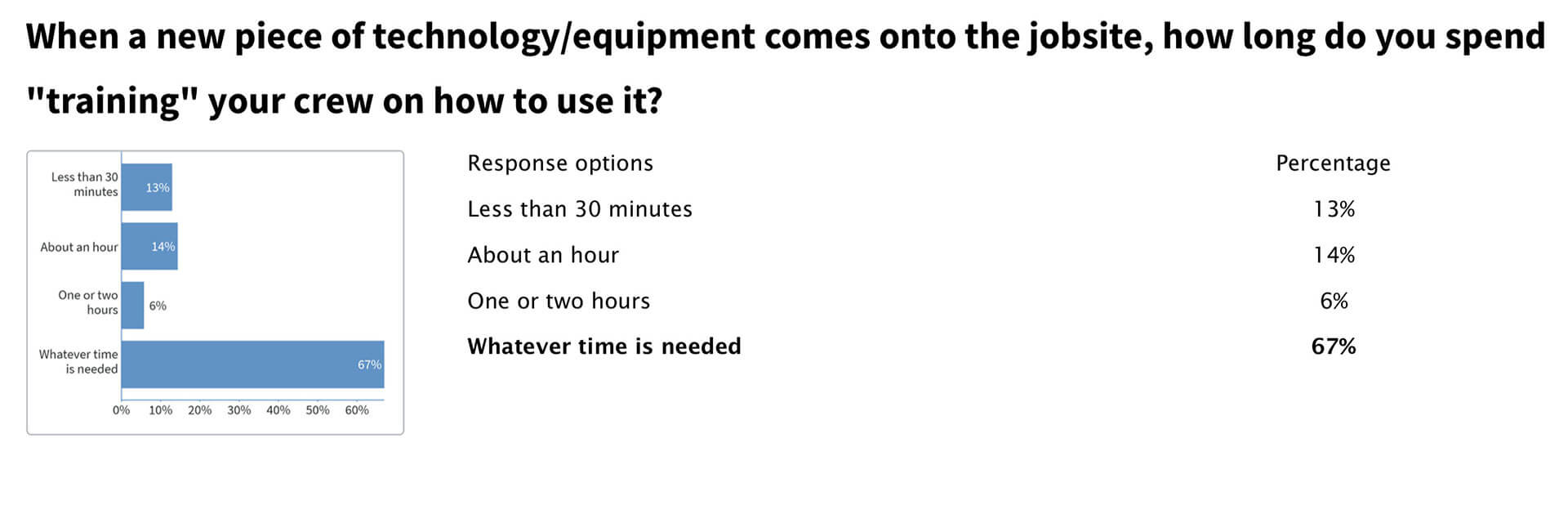

Whenever a new process, tool or technology is introduced to a company, there is always concern about how it will be used by the people in the field every day. At the Indianapolis Field Leaders Conference, UA Director of Training Chris Haslinger made a presentation about construction technology. His presentation included a survey which yielded some very interesting results from 175 end users.

A balance must always be made in technology training. You don’t want to spend so much time on the training process that it keeps people from doing their jobs. You also want to make sure that people understand how to use it and follow up with added training if required. The good news from these results is that it seems like most field users are getting the right amount of time, regardless of the duration, and very few respondents appear to be getting new technology handed to them with little time to practice with it.

A balance must always be made in technology training. You don’t want to spend so much time on the training process that it keeps people from doing their jobs. You also want to make sure that people understand how to use it and follow up with added training if required. The good news from these results is that it seems like most field users are getting the right amount of time, regardless of the duration, and very few respondents appear to be getting new technology handed to them with little time to practice with it.

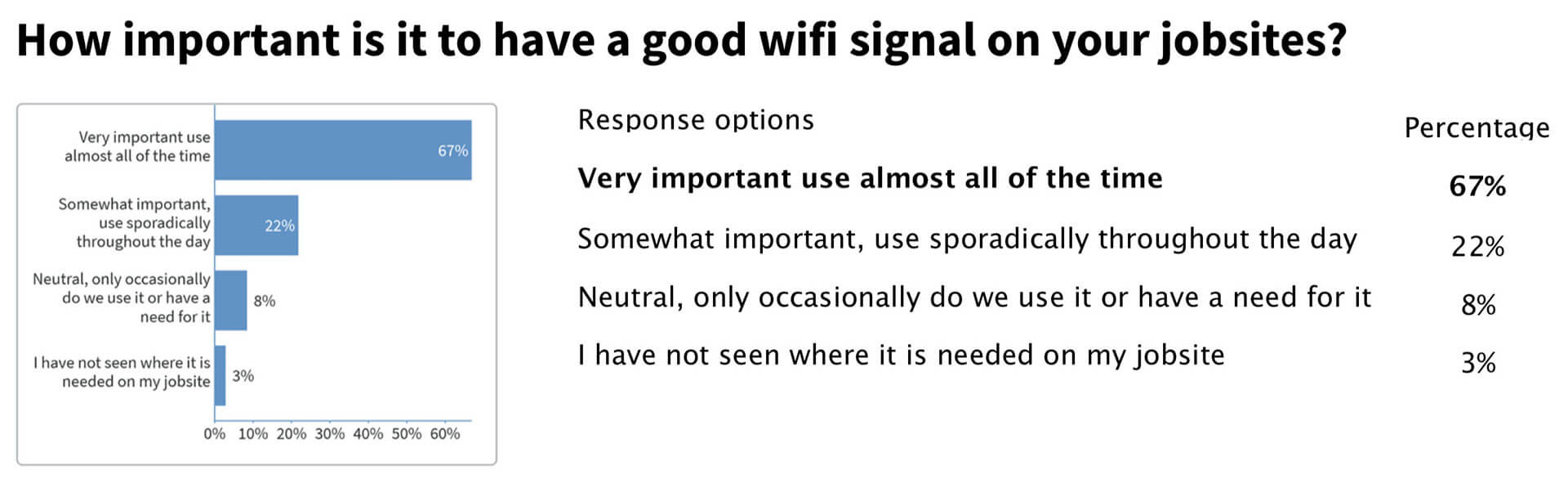

The next question focused more on the tools needed to use new technology on the job site. As mobile devices are frequently seen as required tools by foreman and field supervisors, the need for internet connectivity has risen significantly.

Two thirds of field leaders answered that it is not only very important, but almost all of the time. This speaks to how essential communication and data flow is becoming between the field and the office. Today, field employees are using their mobile devices for more processes and a good internet connection is becoming a necessity. A poor internet connection slows down the processes and can waste field time. This makes usage of mobile devices counter-productive when the time it takes for files to load or transfer make it slower than other methods.

The usage of mobile devices is increasing. Much of this has to do with better software applications on the market and more companies making it part of the process. When asked which software applications they used most frequently, they responded:

- 85% – Jobsite Documentation

- 75% – Blueprint Rendering

- 67% – Time Cards

- 19% – Tool Management

- 46% – Safety Related Purposes

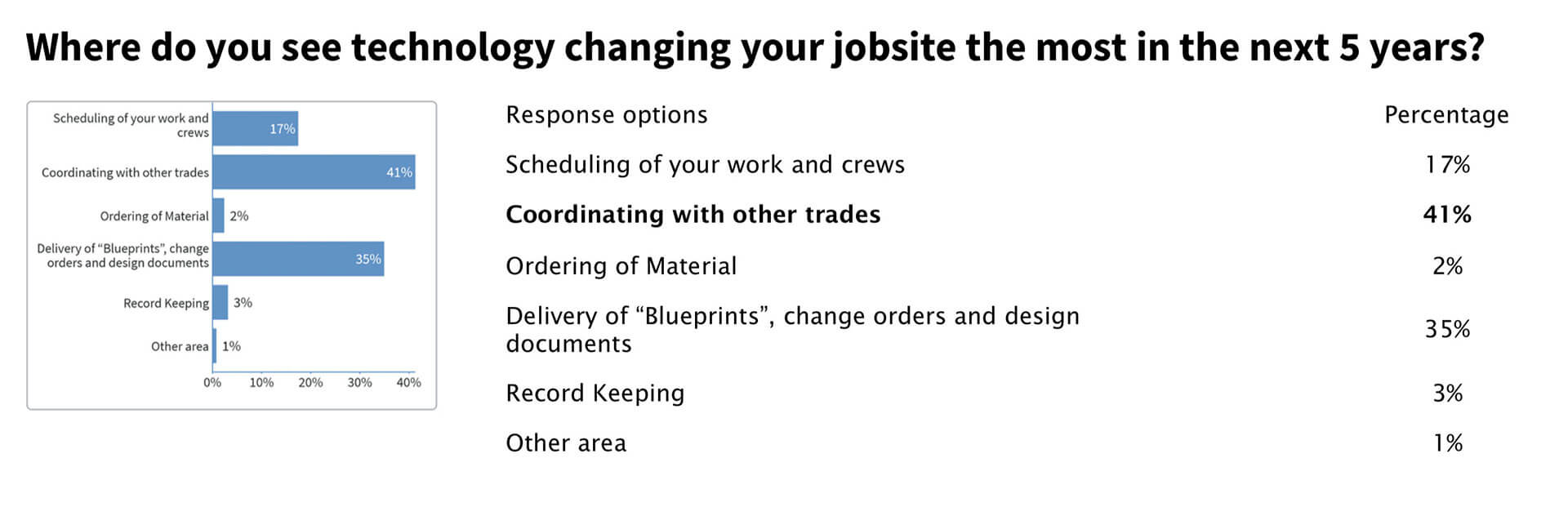

This demonstrates heavy usage of applications across a diverse set of processes. With a higher rate of application usage, the industry is likely to modify its processes to compensate. The last survey focused on this issue.

The top two responses both involved improved communication. Coordination with other trades is a process that has a high need for improvement, but involves a process improvement for communication. The same could be said of delivery of blueprints, change orders and design documents – a process that can grind a project to a halt and add significant cost if not organized correctly.

Mobile devices and job site software have become normal for modern contractors. To keep up on technology impacting MCAA members, MCAA’s Technology Initiative will continue to provide research, articles and guidance.