WiMI Minute – Meet the Women of WiMI: Stacy Zerr

This month we feature Stacy Zerr, Director of Preconstruction Services, The Waldinger Corporation.

This month we feature Stacy Zerr, Director of Preconstruction Services, The Waldinger Corporation.

For 2020, MCAA has updated its student internship grant process to focus on the intern and give them the best opportunities possible with MCAA member companies. Five-hundred-dollar grants will now be offered directly to students who accept internships or full-time positions, with funding from MCERF.

Having MCAA interns working at member companies is a win-win for the mechanical contracting industry. Employers get top talent and build a pipeline of future employees. Students gain experience, create connections, develop skills and further their interest in mechanical contracting. In paying the student instead of the employer, MCAA’s goal is to increase the overall number of interns and drive the overall number of talented employees accepting full-time positions after graduation.

MCA of Metropolitan Washington (MCAMW) member The Bowers Group, also known as W.E. Bowers, hired Andrew Nguyen, a junior at Virginia Polytechnic Institute, for a summer internship. Read the story here.

In 2019, BMWC Constructors, Inc. used an internship grant to for Purdue University Senior Madelyn Conway’s summer internship. She will join the company full-time following graduation. Read the success story here.

The MCAA member company will first ensure a prospective intern is in good standing at an accredited two- or four-year college, university or technical school. While MCAA encourages its members to give priority to students from the MCAA Student Chapter Program, this is not a requirement to receive a grant.

Each MCAA member company can submit up to two internship grant applications per year. Once an application is reviewed and accepted, MCAA will send a $500 Visa Gift Card to the member company so it can present the Gift Card to the student at the start of their internship.

MCAA will follow-up with each company and intern to ensure the process and overall internship was successful.

MCAAGreatFutures.org gives members access to student profiles and resumes. The profiles are searchable by university, desired location, and even a specific skill set, like BIM or AutoCAD. A keyword filter allows users to zero in on students who fit the bill.

Not finding a match? Try reaching out to our 60 MCAA Student Chapters. The chapter advisors are a great resource to help find the right person. And, MCAA members have exclusive access to post job openings on our job board.

Help build our industry’s GreatFuture – apply for a grant!

In this month’s Beyond the Classroom, meet MILWAUKEE TOOL’s Territory Manager, Hyojon Robbins, who highlights the unique opportunities available to students who choose careers working for a manufacturer/supplier. Upcoming Beyond the Classroom videos will showcase how MCAA student chapter members and MCAA members alike are benefiting from the program. They will also share the opportunities available to students who choose careers in the mechanical industry.

MCAA is currently accepting applications for its flagship executive education program, the Advanced Leadership Institute. Designed specifically for mechanical contracting executives, the ALI is focused on developing the talents and business networks of leaders in the industry.

MCAA is currently accepting applications for its flagship executive education program, the Advanced Leadership Institute. Designed specifically for mechanical contracting executives, the ALI is focused on developing the talents and business networks of leaders in the industry.

The intensive, team-oriented, two-week residential program includes lecture, individual coaching sessions, and the development and presentation of final a team project.

The ALI is offered annually at Babson College in Wellesley, MA. The dates for ALI Course 20 are September 13-17, 2020 and November 1-6, 2020.

The application process is competitive, and applicants must provide the endorsement of their CEO/President. While the deadline is May 29, 2020, the course fills up quickly, so early submission is recommended.

For additional program details and application criteria, download the application form.

A new Dodge Data & Analytics study of mechanical and HVAC contractors using BIM shows that most mechanical contractors that use BIM experience benefits such as improved cost and schedule performance, lower labor costs and greater productivity. MCAA partnered with Dodge to produce the report, which includes input from many MCAA members.

The Business Value of BIM for Mechanical and HVAC Construction SmartMarket Report based on the study’s findings provides a comprehensive examination of the benefits that mechanical contractors experience when using BIM as well as the challenges they face in expanding BIM use.

The study demonstrates that mechanical contractors are sophisticated users of BIM software who have seen the benefits from that use. However, the study also shows that the ability of these contractors to fully leverage the value of modeling technologies is hampered by training and manpower issues, along with the challenge of getting other project stakeholders equally engaged in BIM.

One of the biggest benefits reported by contractors is the ability of BIM to improve the fabrication process. Many mechanical contractors are frequent users of offsite fabrication for their systems, and the study shows that nearly half use BIM on 50% or more of the assemblies they prefabricate, demonstrating that BIM is an essential tool for this process. Benefits from using BIM to aid prefabrication are widely reported, with over 80% of mechanical contractors who use it to prefabricate reporting that they see improvements in the material waste generated, labor costs, quality of installed work, avoiding the purchase of extra pipes and fittings and schedule performance.

Other top benefits reported by contractors using BIM in general are increased labor productivity, increased profitability, better utilization of resources and improved cost performance.

“BIM is an increasingly important and incredibly complex part of the building process. It requires additional coordination, planning, and design expertise, and MCAA members are embracing the tools and technology to rise to the challenge. This new process is still in its infancy, and mechanical contractors—especially those that are already using BIM—have a lot to learn from this report.”

–Sean McGuire, Director, Innovative Technologies, at MCAA

By using BIM, mechanical contractors have also been able to leverage the technology to conduct more analysis on their projects.

• Over 70% report that they use BIM for shop drawings and spatial coordination on half or more of their projects.

• Nearly two thirds (61%) report using BIM for constructability evaluation on more than half of their projects.

“Use of BIM for spatial coordination and constructability evaluation provides these contractors with a clear advantage,” says Steve Jones, Senior Director of Industry Insights at Dodge Data & Analytics. “They can address issues before construction begins, which saves both time and money, and can even help improve safety by avoiding rework.”

However, there are still challenges that prevent these contractors from fully leveraging the use of BIM. The biggest challenges include training needs for employees and lack of available manpower to create BIM models. In addition, these contractors struggle with full engagement with BIM across the project team, with lack of support for BIM from other important trades, the issue of other stakeholders on their projects not using BIM and poor-quality BIM use by other stakeholders also presenting significant challenges. Addressing these issues will allow even more contractors to more fully experience the benefits of using BIM collaboratively on their projects.

MCAA’s Virtual Trade Show connects our contractor members with the members of MCAA’s Manufacturer/Supplier Council.

Participating companies highlight and link to new products, product lines, services, solutions or web pages of particular interest. Here are just a few of the recent additions:

Watts Water Technologies

Time is money. And with Watts Learn & Earn program, you can earn tokens for swag in less than 10 minutes. Learn about Watts products on demand from any device, collect, and get on with your day.

Jay R. Smith Mfg. Co.® a Member of Morris Group International

We designed this labor saving floor drain stabilizer assembly with multistory building construction in mind. Multiple floors mean multiple drains and an increased risk of some of those drains falling over or being knocked out of position prior to and during the pour. Simply mount this assembly directly onto the “fly-away” form and you eliminate the need to spend time and manpower going from floor to floor resetting misaligned drains.

Find many more smart solutions in MCAA’s Virtual Trade Show!

Visit the Smart Solutions Case Studies area of our website to learn how other mechanical contractors found their win-win with cost-saving and productivity-enhancing applications from members of MCAA’s Manufacturer/Supplier Council.

This section of our website also includes tips and ideas to help your company save money and enhance your productivity. Don’t miss it!

Jonathan Dang has accepted a full-time position with Freitag Weinhardt, Inc., in Terre Haute, Indiana. He is interning for the company while he completes his studies at Indiana State University, where he is pursuing a B.S. in Safety Management with a minor in Construction Management. He will join the company as an employee after graduation in December 2020.

Jonathan, who is the president of the MCAA Student Chapter at Indiana State University, noted that “one of the things that made a career in the mechanical industry so appealing is the investment in students and their futures.”

He went on to describe the experiences that led to his career choice. “When I started to pursue my college degree, I did not know what I wanted to be. Until I was given the opportunity to go to my first MCAA GreatFutures Forum in 2018 in Anaheim. I never understood how amazing MCAA and all its members can be. From the latest technology to the passion of all the individuals there, I was awestruck and, at that moment, I was all in.”

He went on to describe the experiences that led to his career choice. “When I started to pursue my college degree, I did not know what I wanted to be. Until I was given the opportunity to go to my first MCAA GreatFutures Forum in 2018 in Anaheim. I never understood how amazing MCAA and all its members can be. From the latest technology to the passion of all the individuals there, I was awestruck and, at that moment, I was all in.”

Jonathan met Bob Moreland and Mark Ungar from Freitag-Weinhardt, Inc. at an MCA of Indiana event during MCAA19 in San Antonio. “They offered me an internship at their office, and I took it,” he said. “During my internship, I have learned how to do estimating, subcontracts, POs, and change orders, and I understand how people operate in the field.”

Jonathan also attended the 2019 MCAA GreatFutures Forum in Washington, D.C. He said, “No matter how many MCAA events I attend, I am always blown away by the fact that MCAA is willing to invest much of their resources in college students like me. I look forward to the future that MCAA is building.”

You can find student chapter members like Jonathan at mcaagreatfutures.org.

Federal OSHA recently informed its regional and area offices that the agency is implementing a National Emphasis Program (NEP) to identify and reduce or eliminate worker exposures to respirable crystalline silica. The NEP targets specific trades in the construction industry. North American Industry Classification System (NAICS) code# 238220 (Plumbing, Heating, and Air-Conditioning Contractors) is being targeted. This means that OSHA’s compliance officers nationwide will be emphasizing inspections/enforcement where respirable crystalline silica could be generated in our trade. MCAA recommends that you verify that your company is in compliance with the OSHA standard… Respirable Crystalline Silica.

MCAA has several safety resources to help you protect your workers from overexposure to respirable crystalline silica and comply with OSHA’s silica standard, including:

![]()

For 2020, MCAA has updated its student internship grant process to focus on the intern and give them the best opportunities possible with MCAA member companies. Five-hundred-dollar grants will now be offered directly to students who accept internships or full-time positions, with funding from MCERF.

Having MCAA interns working at member companies is a win-win for the mechanical contracting industry. Employers get top talent and build a pipeline of future employees. Students gain experience, create connections, develop skills and further their interest in mechanical contracting. In paying the student instead of the employer, MCAA’s goal is to increase the overall number of interns and drive the overall number of talented employees accepting full-time positions after graduation.

The MCAA member company will first ensure a prospective intern is in good standing at an accredited two- or four-year college, university or technical school. While MCAA encourages its members to give priority to students from the MCAA Student Chapter Program, this is not a requirement to receive a grant.

Each MCAA member company can submit up to two internship grant applications per year. Once an application is reviewed and accepted, MCAA will send a $500 Visa Gift Card to the member company so it can present the Gift Card to the student at the start of their internship.

MCAA will follow-up with each company and intern to ensure the process and overall internship was successful.

MCAAGreatFutures.org gives members access to student profiles and resumes. The profiles are searchable by university, desired location, and even a specific skill set, like BIM or AutoCAD. A keyword filter allows users to zero in on students who fit the bill.

Not finding a match? Try reaching out to our 60 MCAA Student Chapters. The chapter advisors are a great resource to help find the right person. And, MCAA members have exclusive access to post job openings on our job board.

Help build our industry’s GreatFuture – apply for a grant!

Genie has been notified of three instances where the bottom turntable rotation bearing bolts in specified machines have come loose causing the separation of the turntable from the chassis. Separation of the turntable from the chassis can result in a machine tip-over or other structural failure. Use of all affected machines must be stopped immediately until appropriate corrective action is completed. Affected models and serial ranges are:

Machines with a year of manufacture 2019 up to the release date of this notice:

Model Serial Range

S-65 S60H-39903 to 40455

S-60XC & S-65XC S60XCH-45009 to 46426

S-60XC & S-65XC S65XCH-45007 to 46425

S-60X S60XH-39397 to 40454

Machines with a year of manufacture between 2015 and 2018:

Model Serial Range

S-65 S6015H-35001 to 35031

S-65 S6016H-35032 to 36172

S-65 S60H-36400 to 40438

S-60 TRAX & S-65 TRAX S60TX16H-35555 to 36014

S-60 TRAX & S-65 TRAX S60TXH-36581 to 40150

S-60 TRAX & S-65 TRAX S60TX16H-35463 to 36161

S-60 TRAX & S-65 TRAX S60TXH-36437 to 40198

S-60 TRAX & S-65 TRAX S65TXH-40225 to 40225

S-60X S60X16H-35034 to 36171

S-60X S60XH-36401 to 40456

S-60XC & S-65XC S60XC16H-35119 to 36114

S-60XC & S-65XC S60XCH-36472 to 45011

S-60XC & S-65XC S65XCH-45001 to 45010

MCAA’s Virtual Trade Show connects our contractor members with the members of MCAA’s Manufacturer/Supplier Council.

Participating companies highlight and link to new products, product lines, services, solutions or web pages of particular interest. Here are just a few of the recent additions:

Daikin Group

Daikin North America LLC (DNA) has announced the launch of VRV IV-S-series heat pump – The next generation “Mini-VRV” for residential and light commercial applications.

Trimble

By connecting key workflows between estimating, design and installation, Trimble helps MEP contractors reduce project risk while increasing overall productivity and efficiency.

Find many more smart solutions in MCAA’s Virtual Trade Show!

Visit the Smart Solutions Case Studies area of our website to learn how other mechanical contractors found their win-win with cost-saving and productivity-enhancing applications from members of MCAA’s Manufacturer/Supplier Council.

This section of our website also includes tips and ideas to help your company save money and enhance your productivity. Don’t miss it!

Every year, the MCAA Technology Conference brings ideas and innovation to MCAA members. This year’s event was no exception. Take a look, and plan to join us next year. MCAA thanks our title sponsor, Trimble, and our event sponsors: Autodesk, DEWALT and Rhumbix.

Kim Bassett, President and CEO of Bassett Mechanical, and Charles A. Bacon, III, CEO of Limbach Facility Services, have been named to Safety+Health magazine’s list of 2020 CEOs Who “Get It.” This annual recognition is presented to safety leaders who go the extra mile to protect employees both on and off the job, as nominated by readers. “I do many things in my role as president and CEO,” Kim said, “but doing my best to keep our associates safe is by far the most important.”

MCAA congratulates Thomas Walsh for accepting a full-time position with U.S. Engineering Innovations. Thomas is a graduate of the University of Missouri-Columbia with a B.S. in Mechanical Engineering. He was a presenter in the MCAA19 Student Chapter Competition Final Four in Phoenix, Arizona where he also received the Reilly Family Memorial Scholarship, sponsored by the John W. Danforth Company.

Thomas reflects on how his experiences with MCAA, the MCA of Eastern Missouri and his student chapter helped him find his great future in the mechanical industry:

My experience with the MCAA student chapter was instrumental in helping me find full-time employment in mechanical contracting. I first met U.S. Engineering at the 2018 MCAA Great Futures Forum in Anaheim with the Missouri-Columbia student chapter where I applied for an internship. During interviews for this internship, I was able to speak at great length about my involvement in the MCAA student chapter and the annual competition. The interviewees were very impressed with my work on the competition and how easily it translated to the work they do every day as mechanical contractors.

I had the opportunity to present part of Mizzou’s competition proposal on stage at MCAA19 in Phoenix which played a big role in helping me become a better public speaker and presenter.

My internship with U.S. Engineering was amazing. I primarily worked alongside Preconstruction Managers and Project Managers. One of the larger responsibilities I had was to put together a full mechanical bid from design documents for a potential project. I was also responsible for acquiring and reviewing quotes from vendors for large mechanical equipment. I shadowed project controls to learn more about scheduling and real estate to learn more about renovations. My internship with U.S. Engineering was primarily so rewarding, because I was able to pursue parts of contracting that I found interesting.

Because my internship was so rewarding, I accepted a full-time opportunity with U.S. Engineering Innovations. I will be returning to work with the same team that I interned alongside. At my full-time position, I will work as a Preconstruction Engineer creating bids and proposals, estimating change orders, and assisting in scheduling. I will also work as a project engineer to assist in logistics, procurement and quality control of our ongoing projects. I will have the opportunity to travel to some of our sites and assist in and experience construction in the field.

Findings of a landmark Dodge Data & Analytics study on the use of fabrication and modular construction show that most design and construction professionals using these methods experience improved productivity and project quality, plus increases in schedule certainty. MCAA partnered with Dodge to produce the report, which includes input from many MCAA members.

The Prefabrication and Modular Construction SmartMarket Report based on the study’s findings provides a comprehensive examination of the current state and future expectations for prefabrication and modular construction. It takes a close look at critical drivers, obstacles and benefits of using these methods, based on insight from architects, engineers and contractors already leveraging them.

The report shows that architects, engineers and contractors that have used these methods plan to significantly increase their engagement with them, especially for healthcare facilities, hotels and motels, multifamily projects, and college buildings and dormitories, which are at the vanguard of the new wave of interest in these methods. Critical trends in the construction industry, such as shorter project schedules and workforce shortages, are driving wider use of these methods, and technology like building information modeling (BIM) is enabling increased use.

In order to better understand the critical drivers and obstacles for using these methods and the benefits achieved, the study focuses on the architects, engineers and contractors that are already using them.

When it comes to methods already in use, the study shows that:

However, most interesting growth is expected in practices less widely used now:

“It comes as no surprise to us that more developers and GCs plan to use modular construction over the next few years,” said Tom Hardiman, Executive Director of the Modular Building Institute. “The lack of adequate housing and the shortage of skilled labor, coupled with chronic cost and schedule overruns are leading more people towards this process.”

And when it comes to benefits of use:

The use of building information modeling (BIM) is also tied to the experience of those benefits. Among those using BIM on the majority of their projects, 60% credit it with improving the schedule performance of their prefabricated or modular projects, and 50% with improving budget performance. “BIM improves the prefabrication and modular process by providing the means to accelerate the design early enough to take advantage of these approaches and then offering certainty during the entire process,” says Steve Jones, senior director of industry insights at Dodge Data and Analytics. “Having these tools helps enable the industry to invest more in the use of multi-trade assemblies and volumetric construction in particular and may be contributing to the strong growth expected in these areas.”

The greatest growth in the use of these methods will be in building types in which they are already well established, such as healthcare facilities, hotels and motels, multifamily and college buildings and dormitories. However, a sizable percentage also expect low-rise offices, K-12 schools, public buildings and commercial warehouse to experience a high frequency of use of prefabrication or modular construction.

The report findings will be discussed during a general session at the MCAA Technology Conference.

Check out the pictures from MCAA’s 17th Annual Safety Directors Conference (SDC) where a record number of attendees, including member safety professionals, UA safety instructors, and MCA local executives came together for world class education on the safety and health topics and issues that are currently affecting the mechanical construction and service industry. This conference marks the 17th consecutive year of record attendance. Join us next year in San Diego for SDC-2021, January 19-21.

MCAA’s Virtual Trade Show connects our contractor members with the members of MCAA’s Manufacturer/Supplier Council.

Participating companies highlight and link to new products, product lines, services, solutions or web pages of particular interest. Here are just a few of the recent additions:

Jay R. Smith Mfg. Co.® a Member of Morris Group International

The Guardian Dual Check hydrant, with the box, is the go-to choice for contractors working on brick façade buildings. This ergonomic hydrant is designed to fit into the space of one standard brick for easy installation. That adds up to significant time savings because you eliminate extra cuts and mortar repair. Discover more products that save you time on the job.

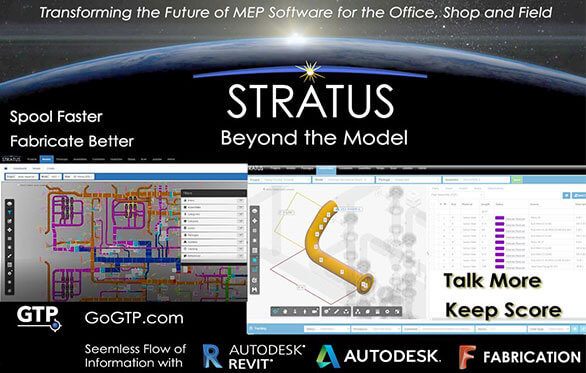

GTP Services, LLC

STRATUS, the premiere Virtual Design and Construction Productivity software solution for MEP Contractors, takes you beyond the model. Elevate your technology capabilities in the shop and field. Empower your team with information. Encourage more communication and engagement.

Find many more smart solutions in MCAA’s Virtual Trade Show!

Visit the Smart Solutions Case Studies area of our website to learn how other mechanical contractors found their win-win with cost-saving and productivity-enhancing applications from members of MCAA’s Manufacturer/Supplier Council.

This section of our website also includes tips and ideas to help your company save money and enhance your productivity. Don’t miss it!

Mechanical industry safety professionals and UA safety instructors came together for world-class education on the most current, mechanical industry-specific safety and health topics and issues during MCAA’s Annual Safety Directors’ Conference. MCAA thanks CNA and MILWAUKEE TOOL for sponsoring the event.

Thank you to everyone who supported the MCAA PAC in 2019. With your support, the MCAA PAC can continue its efforts to gain our members and our industry a fair hearing in federal public policy decisions.

Those supporting the MCAA PAC from January 1, 2019 – December 30, 2019 were:

MCAA PAC appreciates your support.

Molly Sizemore has accepted her second summer internship at Southland Industries, a member of the MCA of Metropolitan Washington.

She will be interning in the company’s engineering department, where she will work on mechanical and plumbing systems projects in Navisworks and Revit. Last summer, she saw the project management side of the industry as an intern on a data center project in Ashburn, Virginia.

Molly said, “working on a data center opened my eyes to understand different heating and cooling systems since they’re so MEP-heavy and mission critical. Southland has opened many doors of opportunity in the past year – one of them being MCAA.”

Molly learned about the opportunity to be part of a MCAA Student Chapter during her internship last summer. There, she met Lauren Boyle, a Southland Industries design engineer and a past member of the MCAA Student Chapter at the Pennsylvania State Univers ity, also known as Penn State. Lauren told Molly about MCAA and the resources that would be available to her.

ity, also known as Penn State. Lauren told Molly about MCAA and the resources that would be available to her.

Molly worked with her faculty advisor and her local association, the MCA of Central Pennsylvania, to help the Penn State University chapter gain momentum and even participate in this year’s MCAA Student Chapter Competition. She said, “Participating in the competition has been a really unique experience in my college career.”

Molly also attended the 2019 GreatFutures Forum in Washington, D.C., where she was, “…blown away by the friendly faces of both students and professionals along with the engaging and fulfilling content of the conference.”

Molly is looking forward to attending MCAA2020 in Maui and expanding her network before heading to Washington, D.C. for her internship.

“MCAA has definitely created a springboard for me into the mechanical contracting industry, and I’m very excited to continue this journey and get others involved,” she said.

You can find student chapter members like Molly on mcaagreatfutures.org.