A coal-burning power plant in Gallatin, TN, chose Apollo® Valves from Aalberts integrated piping systems for a vital environmental upgrade. Apollo Valves products were selected for their reliability, durability, and precision—crucial characteristics in managing the slurry of limestone that neutralizes sulfur dioxide in flue gasses.

The project involved the installation of scrubber technology. Scrubbers are essential for cleaning gasses emitted from smokestacks. They play a pivotal role in reducing air pollution and curbing the formation of acid rain, which aligns with national efforts to meet stringent Clean Air Act regulations.

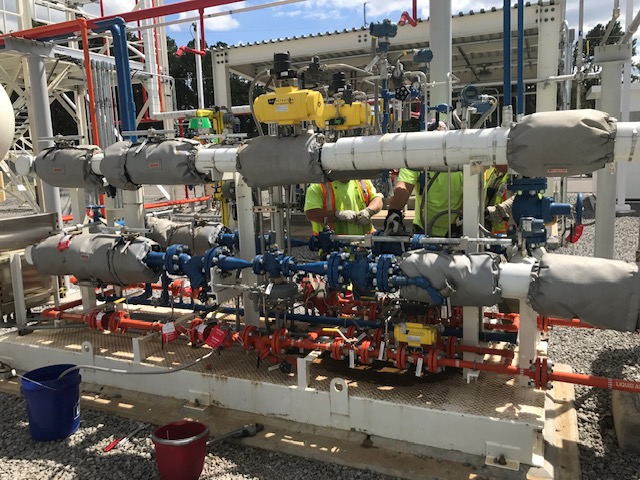

Specifically, the project used 1½” through 4” 87A-90X-24, 300 class full port stainless flanged Apollo Valves. These valves are equipped with AS spring return pneumatic actuators.

Approximately 130 Apollo actuated valves were integrated into the scrubber system. The successful implementation of these valves not only ensured operational efficiency but also enhanced environmental compliance, significantly reducing sulfur emissions from the plant.

This scrubber project is a testament to how Aalberts integrated piping systems and its Apollo Valves brand support the power industry’s transition to more sustainable operations. It exemplifies how industrial applications can achieve environmental goals through technological innovation.

For more information, visit aalberts-ips.us.