With a large project on the horizon and more on the way, AMS Industries, Inc. invested in a Watts Specialties, LLC pipe cutting machine and immediately reaped benefits. “Pipe cuts that were previously taking one man 40 hours to complete are now being cut in 8 hours—including olets!” said Beth Thullen, fabrication shop superintendent at AMS.

Keeping Up the Pace

AMS has built their reputation over five decades of serving clients in multiple industries. They aim to build a better, stronger, and more durable company for the future; protect the AMS brand; and meet their commitments to clients to help improve local communities.

Thullen started her career in 2007 as an apprentice in UA Pipefitters Local 597 and has been with AMS Industries for 12 years. “The last three years we have seen numerous changes and a substantial increase in shop fabrication for commercial and nuclear piping,” she said. “Fortunately, we have stayed extremely busy, and despite having a great team, we are always looking for ways to be more efficient. Previously, we were mainly using a bandsaw, magnetic torch, and different types of pipe and prep machines. We were also renting equipment, doing repairs, and buying replacement parts.”

Thullen continued, “We pride ourselves on being competitive and finding ways to speed up our pipe fabrication flow. Accelerating the steady output of pipe was a priority. Each pipe cut was taking around 15 minutes, followed by an end-prep machine. One of our largest projects was coming due in 2023, with more projects scheduled for 2024. Simply put, we needed a more efficient way to cut pipe.”

AMS began discussions about purchasing a new CNC pipe cutting machine. “The only company mentioned was Watts Specialties,” said Thullen. “We lined up a trial period with a Watts machine at another fabrication shop in the spring of 2021. One of our machine operators worked in this facility for a month, cutting pipe for AMS projects on the Watts machine. We quickly realized an automated pipe cutting machine was the solution for our efficiency goals.”

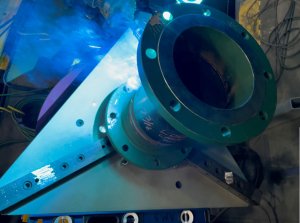

AMS purchased a W-244 pipe cutting machine with a 25’ conveyor system. “We are now cutting a lot more pipe from 6” to 14” outer diameter with more efficiency,” Thullen noted.

Expectations Achieved

“We were hoping for an increase in productivity with a decrease in manhours,” said Thullen matter-of-factly. “As we expected from our trial machine, we have definitely seen an increase in productivity. The cut pipe leaves the machine with clean bevels. The welders are now more efficient, spending less time on layout and fit-up.”

Thullen explained, “We are mostly running prespooled fabrication with a lot of olet holes. We also get regular requests from the field for ‘spur-of-the-moment’ piping needs. It is really nice to be able to quickly design a new spool by simply putting the dimensions in the machine … on the go, then load the spools on a truck and deliver the pipe to the field. This kind of swift flexibility was hard to accommodate prior to having the Watts machine.”

Game-Changing Software

Thullen also appreciates the Watts 3D-Profile Plus Software. “The software is great,” she noted. “The majority of our larger jobs are scanned, modeled, spooled, and moved to a shared file by the drafting department. My operator is able to make decisions about which jobs he uploads on a daily basis.”

Learning the software has been a smooth process, according to Thullen. “Our machine operators, only two months into working with the Watts machine, are very comfortable. The benefit of the software is greatest on bigger jobs when we upload spools to be cut in multiple quantities.”

Moreover, Thullen explained, “The software is also a game changer when we get requests for lateral, mitered, or saddled pipe cuts. It only takes five minutes to design and cut a unique spool. Before we had the Watts machine, it would take one to two hours—calculating coordinates, laying out the project, and then cutting the pipe with a torch or a grinding/cutting wheel.”

AMS has not yet needed to call for support, but, said Thullen, “start-up and training with Jessie Scribner, the lead support technician for Watts Specialties, was super informative. He definitely set us up for success, so we are not overly concerned about what might happen when we need support.”

For more information, visit www.watts-specialties.com.