Through a preventative maintenance program, F.W. Webb Company found and fixed oil leaks at a New Hampshire power plant that could have caused major problems. Instead of a long shutdown that could have affected electricity customers across New England, F.W. Webb completed repairs during a planned two-week plant closure.

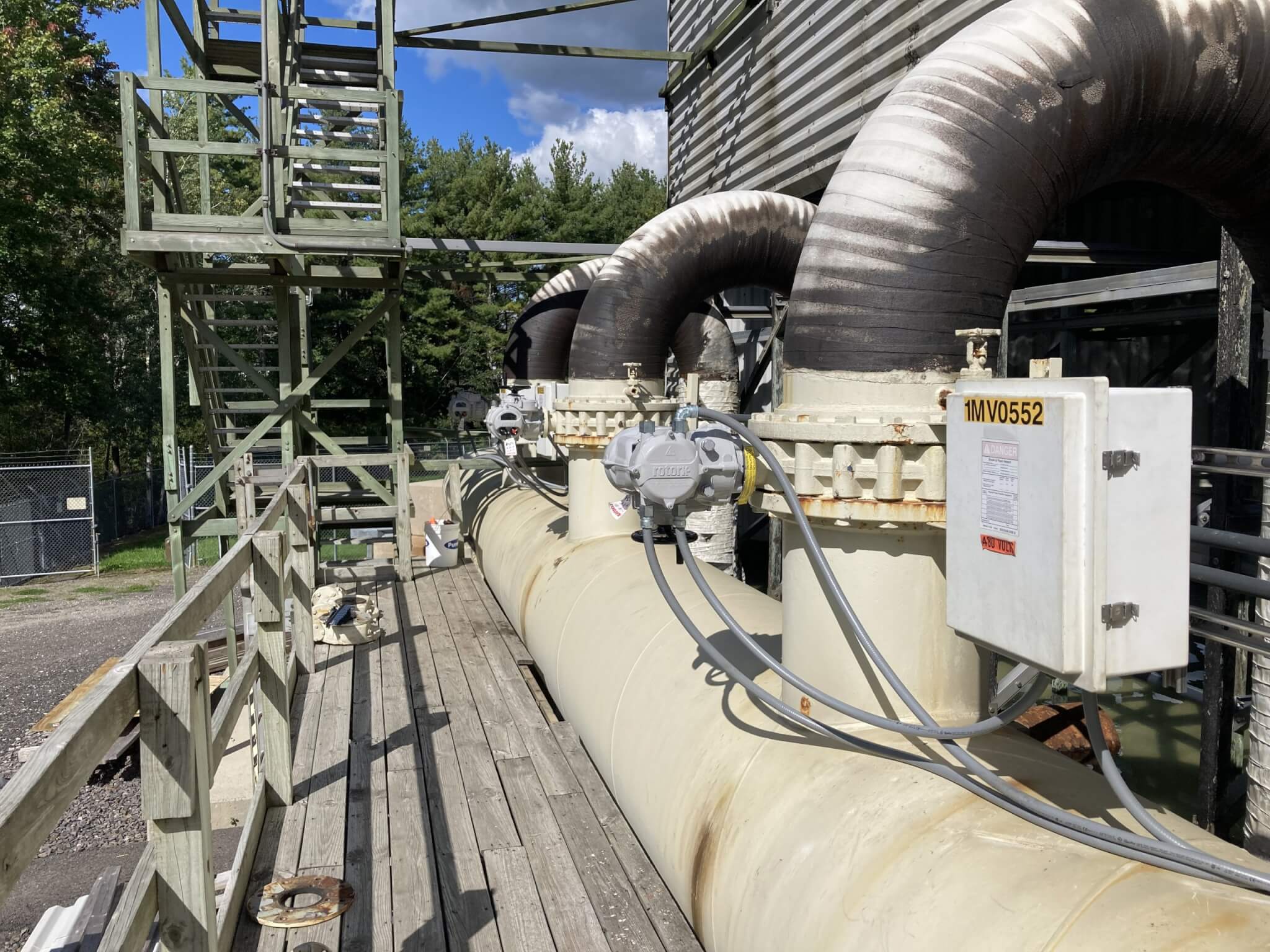

Driven by natural gas, the highly-efficient, clean-burning power plant uses both combustion and steam turbines to serve 745 megawatts of electricity to customers. The power plant engaged Webb’s Process Controls Division to perform preventative maintenance on all of the plant’s motor-operated valves. Webb discovered obscured oil leaks in 44% of the Rotork valves— causing downstream issues related to steam discharge.

Webb identified that heat near the steam generator damaged all the direct-mount electric actuators. The team learned that the plant’s Pakscan™ system had experienced malfunctions since 2019 because of incompatible Pakscan/Siemens cards.

The plant shut down for two weeks to allow Webb’s Rotork Service Technicians to perform the following:

- Identify 54 Rotork-operated valves distributed across a 48-acre facility comprised of two generators interconnected via a Pakscan system.

- Log all settings, performance, inspection, event, and field failure data for each valve, and merge those data with historical and specification data.

- Fix leaks in 24 of the 54 valves.

Although the two-week shutdown was planned, complications compacted the schedule, including a three-day delayed start and a requested weekend reduction in crew size. The plant also required Webb technicians to work 12-hour days. To get the job done, technicians formed two groups of three. One team removed the actuators, while the other rebuilt and prepared them for reinstallation.

The power plant avoided a prolonged shutdown and additional capital expenditures thanks to Webb’s preventative maintenance.

The Rotork actuators now perform to the manufacturer-recommended 20-year lifespan. All valves functioned properly after the plant went back online—and the Pakscan system worked flawlessly too.

Webb’s crews overcame the schedule delay, including actuator rebuilds commencing the second week, to complete the project in 11 days with a 100-percent success rate and without any time lost to injury. The power plant avoided a prolonged shutdown and additional capital expenditures thanks to Webb’s preventative maintenance.

For more information, visit www.fwwebb.com.