MCAA members are innovating and creating new ways to help minimize the impact of COVID-19. Tweet/Garot Mechanical, Inc. of De Pere, Wisconsin, is just one example. In partnership with the teams at HGA, Boldt, Faith Technologies and IMEG, they provided an acute care solution in under two weeks.

An Innovative Project Approach

With the majority of the team working remotely, Tweet/Garot and their partners had to be innovative in their collaboration. The project kicked off with a virtual big room where component teams worked through design constraints and constructability challenges while considering “off-the-shelf” approaches to the project.

As a result, the project used a standard HVAC rooftop unit retrofitted to meet isolation room requirements. This one-model approach allowed component teams to start clash detection while the design continued to evolve.

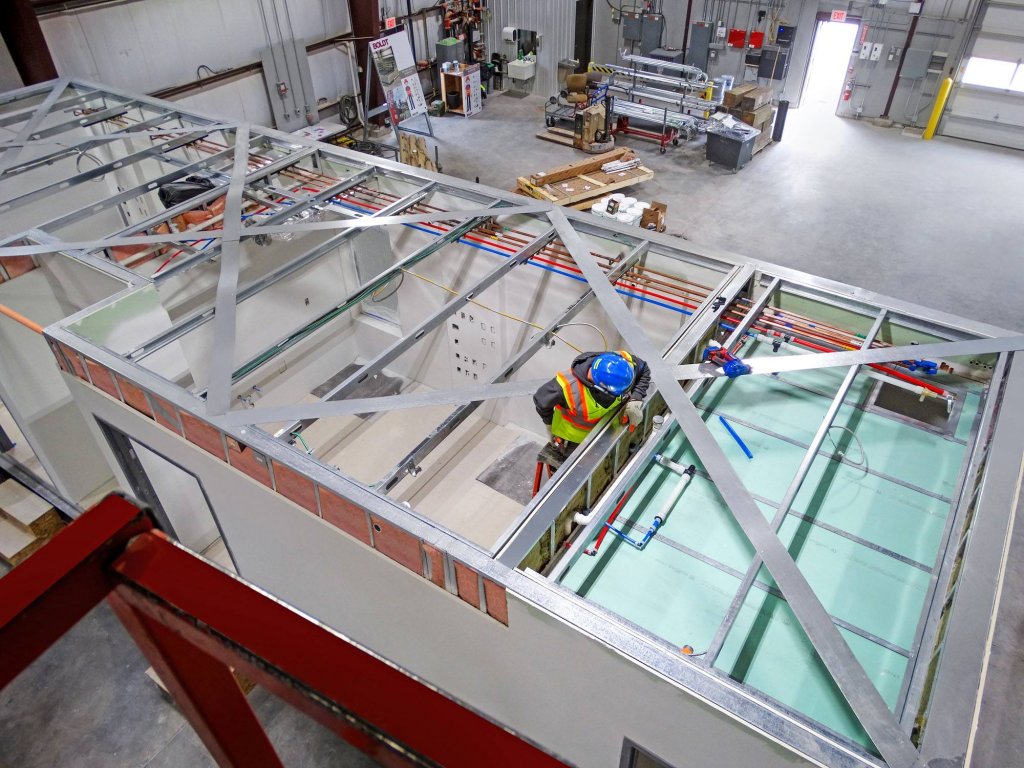

Once design was complete, the manufacturing team worked with Boldt’s facility in Appleton to streamline the production process using pull-plan sessions, completing the project start to finish in less than 10 days.

Prefabricated Modular Solution Offers Flexibility, Quick Delivery

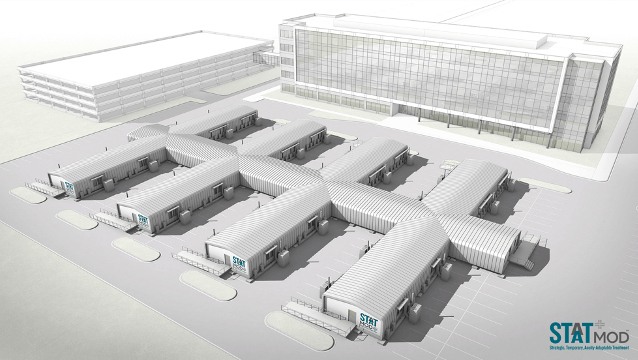

The resulting STAAT ModTM (Strategic, Temporary, Acuity-Adaptable Treatment) prefabricated modular solution can be deployed for use as either stand-alone hospitals or inside convention centers, arenas and temporary structures. It is one of the only temporary care units that can be deployed quickly to provide hospital-level care to patients suffering from coronavirus.

A Variety of Configurations Suit Multiple Applications

The STAAT ModTM solution can be configured as:

- A two-room isolation unit designed for use in an interior shelter, such as a convention center. This unit can be rapidly deployed.

- An eight-bed unit of critical care isolation rooms consisting of four two-bed modules designed to connect to a hospital or existing structure.

- A 12-bed unit of negative-pressure open-bays consisting of four three-bed open bay modules connected to a central support spine. An infinite number of additional self-sustaining tiers can be added.

Enhanced Features Add Safety, Reduce Costs

The STAAT ModTM solution was created and tested with a variety of enhanced features designed to ensure safety, allow for rapid construction and reduce costs. Virtual Reality (VR) simulation exercises allowed experts including critical care nurses trained in COVID-19 protocols, a hospital environmental specialist in infection control, and lean process engineers to test the system during design so that the solution could be constructed and delivered rapidly.

Patients and healthcare workers benefit from:

- Hospital-level clinical care that ensures infection control, access to life-saving technology and isolation rooms if needed for extended periods of time.

- Safety provisions including standardized design, centrally located supplies, and segregated staff workspaces.

- The knowledge that they are providing care that meets CDC guidelines.

Contractors are able to:

- Deliver jobs quickly and with a consistent level of quality. At the same time, contractors are able to better ensure worker safety in the controlled environment of their fabrication shops.

- Deliver cost savings over conventional construction.

Tweet/Garot gained valuable takeaways from the collaborative project. Leadership and trust were maintained among all partners, allowing the design and construction teams to successfully achieve their goals and generate a feedback loop for quick decision-making. Real-time updates from the constant daily collaboration helped address constraints, and ultimately eliminated waste.

This innovative joint effort is helping to pave the way for the healthcare construction market while at the same time minimizing the impact on the community. We’re all in this together.